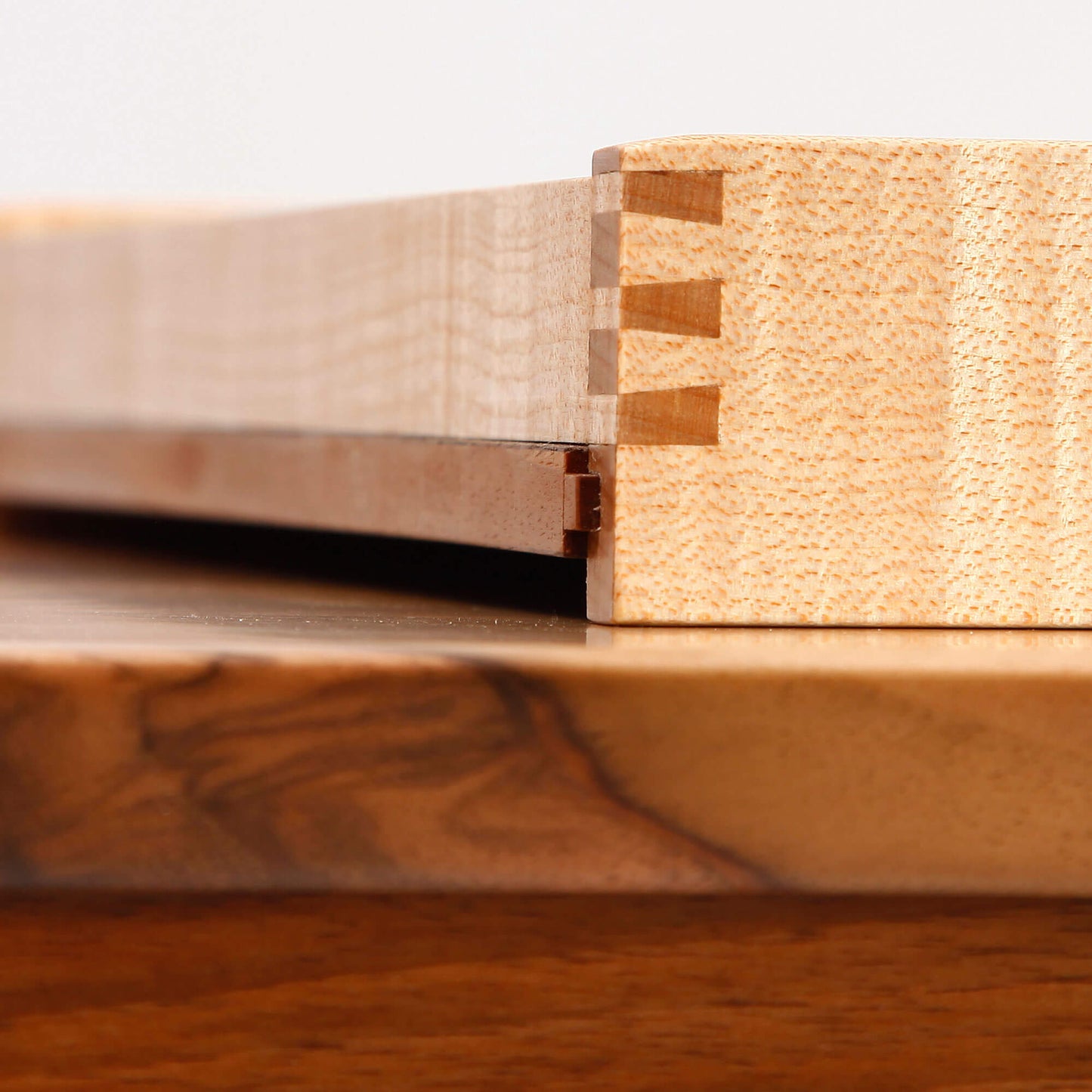

A dovetail joint is called a dovetail because its shape resembles the fan-shaped tail of a dove. The joint consists of a series of interlocking tenons (pins) and mortises (tails) that are shaped like the spread-out tail feathers of a dove, providing a strong and visually appealing connection. The name reflects both the joint's shape and its functionality.

To make a good dovetail joint it must be balanced, the strength versus the load it’s required to take, and hence it must look balanced, too strong and the elements will look bulky and out of place, too light and the potential of breakage or strain will be a disaster. But most of all it allows the right amount of movement and flexibility for the materials joined. This unique design increases the surface area for gluing and provides mechanical strength, making the joint highly resistant to being pulled apart.

Dovetail joints are highly regarded in fine furniture making for several reasons:

Strength and Durability: Dovetail joints are known for their mechanical strength. The interlocking design provides a large gluing area, making the joint very strong and durable without the need for additional fasteners.

Resistance to Pulling Apart: The shape of the dovetail joint makes it extremely resistant to being pulled apart. This makes it ideal for high-stress areas such as drawer fronts and carcass construction.

Aesthetic Appeal: Dovetail joints have a distinct and attractive appearance. The craftsmanship required to make a dovetail joint adds to the overall beauty and perceived quality of fine furniture.

Traditional Craftsmanship: Dovetail joints are a hallmark of traditional woodworking and are often seen as a sign of high-quality craftsmanship. Using dovetail joints demonstrates a woodworker's skill and attention to detail.

Longevity: Furniture made with dovetail joints tends to last longer. The strong joints withstand the test of time, maintaining the structure and integrity of the piece over many years.

Precision: Making dovetail joints requires precision, which often translates to a higher quality overall in the construction of the furniture. This precision ensures that pieces fit together perfectly, enhancing the stability and appearance of the final product.

Versatility: Dovetail joints can be used in various parts of furniture, from drawers to cabinets to carcasses. Their versatility makes them a valuable technique for fine furniture makers.

I follow a specific, traditional technique that follows Robert Ingham’s methods outlined in his book ‘Cutting Edge Cabinet Making’. I use my Felder for the initial stages, squaring and dimensioning. I then use the workbench for setting out, using a scalpel and dividers. The key is scale and appropriateness of the parts combined while being honest to the original design intent and function of the piece.

Having worked for 40 years in fast-paced demanding environments I enjoy this slower process. Dovetail joints are a labour of love, but they are well worth the effort. The result is stunning, they make any simple piece pop with elegance and beauty, contracting grains from end to face catch the light and shine in such a special way. The dovetail joint has become a signature to my fine furniture pieces. The time taken over detail adds to the piece’s beauty and longevity and is a sign of a high-level of craftmanship.