Today, veneer is a staple in the world of fine furniture making. With advances in technology, the process of creating and applying veneer has become more precise and efficient. Whether it's the sleek, modern look you’re after or a classic, timeless piece, veneer makes it possible.

© Williams & Cleal

Composition B

Burr walnut and dyed rippled sycamore veneers.

Inspired by ‘De Stijl’, based on the strict geometry of horizontals and verticals.

© Robert Ingham

Console Table, Sept 2011

Legs and top rail made from American walnut. Top veneered with birdseye maple. Patinated copper decoration between front legs.

Veneering allows for an individual’s style of design and making to shine but it also has many practical benefits such as being more stable than solid wood components where limited wood movement could compromise the structural integrity of a piece, such as at the bottom of drawers where swelling could cause the traditional runners to swell and lock up in winter months.

© John Makepeace

Made for an Arts Council Exhibition in 2010

The marquetry used in the Zebra pieces was laser-cut. Holly wood is quite a rarity, but John was fortunate to acquire a tree from Kew Gardens after the 1987 storms. It is very dense and smooth in contrast to the English oak. John is passionate about forestry and uses the finest of our indigenous hardwoods in the making of furniture of uncompromising quality, both in design and craftsmanship. The Zebras were sold to clients in Guernsey who have subsequently asked John to design a house for them which is now being built. Most of his furniture is made to commission for clients in UK, USA and China.

Marquetry & Parquetry

The processes for marquetry and parquetry are similar to veneering, but they involve more intricate designs and patterns. Both marquetry and parquetry use thin veneers of wood to create decorative surfaces, but they differ in terms of purpose and technique. Here's how these processes compare to standard veneering:

Marquetry

Marquetry is the art of creating decorative patterns or pictures by inlaying pieces of veneer into a surface. It can involve wood, metal, mother-of-pearl, or other materials.

© Colum O’Donovan

Maggie’s Pokémon Cards Box

The selected woods are English Walnut for the sides, Ripple Sycamore for the tray and veneer for the top. These are placed in a circular pattern which reflects the various grain patterns. Cherry veneer is used for the bottom and a motif inlay and some sand scorching has been used to produce the palm tree design.

© Robert Ingham

Gemini, June 2009

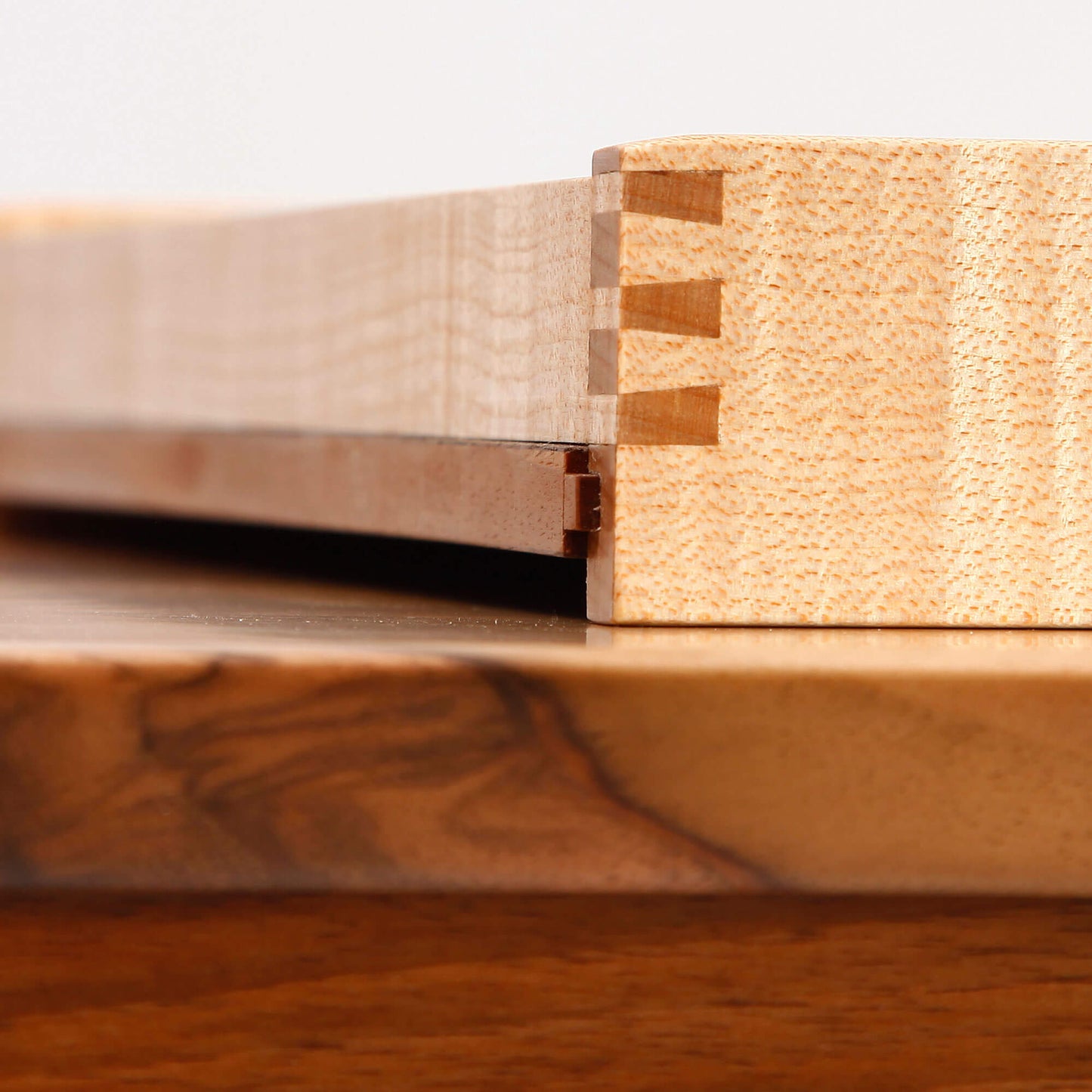

Two lid jewellery box with opposite opening lids lifting up, using side pivot pins. Lids veneered with burr elm. Decorative squares, made from olive ash using marquetry. Box base made from lacewood with hand cut dovetails

The Process of Marquetry

Design Selection: A detailed design or image is created, which will be assembled from individual pieces of veneer.

Cutting the Veneers: Each piece of veneer is carefully cut to fit the design. This can be done using a scroll saw, fret saw, or precision knives. Different types of wood or materials are selected for their color and grain to enhance the visual effect.

Arranging the Veneers: The pieces of veneer are arranged like a puzzle, forming the intricate design on a background veneer or directly on the substrate.

Gluing the Veneers: Once the design is complete, the individual pieces of veneer are glued onto the substrate or backing material.

Pressing: Just like in traditional veneering, the marquetry is pressed (either with clamps or a vacuum press) to ensure a strong bond between the veneer and the substrate.

Sanding and Finishing: The surface is sanded to create a smooth finish. Often, marquetry pieces are polished or varnished to enhance the details and protect the design.

Marquetry is typically used for intricate designs, often found in fine furniture, cabinetry, or artwork.

© Robert Ingham

Ring Boxes, June 2009

Top left. Lid, Veneered American burr walnut. Base, bog oak. Abelone inlaid dots and pivot cap cover. (Oyster shell)

Top right. Veneered burr Swiss pear lid with birdseye maple quadrant. Base, English walnut. Patinated copper pivot cap cover.

Bottom left. Veneered Swiss pear lid with zebrano quadrant. Base wenge.Patinated copper pivot cap cover.

Bottom right. Veneered amboyna burr lid with English burr walnut quadrant.Patinated copper pivot cap cover.

Lids pivot sideways to reveal recesses to store rings or small items of jewellery. Lid patterns created using precision marquetry.

Parquetry

Parquetry involves creating geometric patterns, usually for floors or decorative surfaces. The veneers are cut into geometric shapes and arranged in repeating patterns, rather than forming images or pictures.

The Process of Parquetry

Design Selection: Geometric patterns, like herringbone, basketweave, or chevron, are chosen for the design.

Cutting the Veneers: Veneers are cut into uniform, geometric shapes, often in squares, triangles, or parallelograms. The wood species are chosen based on color and grain for contrast and design clarity.

Arranging the Veneers: The pieces are laid out in the chosen pattern, either directly on the surface to be covered (like a floor) or on a background veneer.

Gluing the Veneers: The pieces are adhered to the substrate or background using glue, just like standard veneering.

Pressing: Pressure is applied to ensure the veneers bond properly to the substrate, which can be done using clamps or a vacuum press.

Sanding and Finishing: After pressing, the surface is sanded smooth. For flooring, a protective finish like varnish or lacquer is applied to protect the parquet design.

Parquetry is primarily used for floors, but it can also be found in furniture and other decorative woodwork.

Comparison with Standard Veneering

Complexity: Marquetry and parquetry are more complex than standard veneering, as they involve creating specific patterns or designs with multiple veneers, whereas veneering usually involves covering a surface with a single piece of veneer.

Veneer Cutting: In standard veneering, the veneer is typically a single sheet applied over a substrate. In marquetry and parquetry, the veneer is cut into many smaller, precise pieces.

Artistic Element: Marquetry is particularly artistic, as it creates images or pictorial designs, whereas standard veneering is typically used for uniform wood grain coverage.

Geometric Focus: Parquetry focuses on geometric designs and is often used in flooring, while standard veneering is used for surfaces like furniture or cabinets.

© Williams & Cleal

Scribe

Silver grey veneer and rippled sycamore.

A contemporary interpretation of the Art Deco style.

This media unit incorporates an infrared extender, allowing the client to operate their AV equipment whilst it is out of sight.

While marquetry, parquetry, and standard veneering all use thin veneers of wood, marquetry focuses on intricate, artistic inlays, and parquetry deals with geometric patterns. The basic principles of gluing and pressing the veneers are the same, but marquetry and parquetry involve more detailed cutting and arrangement of the veneer pieces.

A big thank you to Williams & Cleal, John Makepeace and Robert Ingham for helping with the content of this blog post.